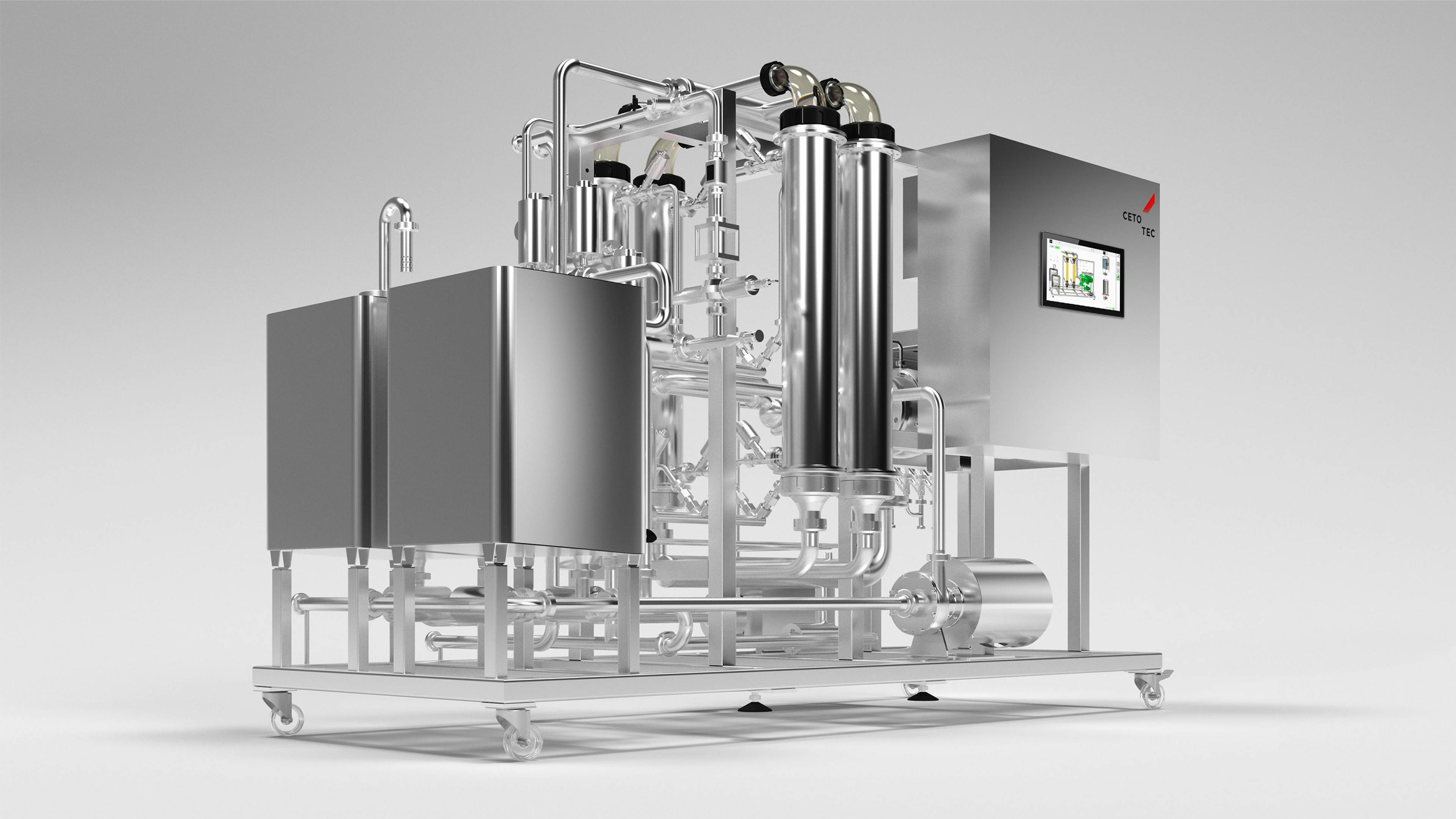

Exhaust air scrubber / Condenser

Cetotec dual-stage exhaust air scrubbers offer, especially for industrial vinegar fermenters and larger quantities of exhaust air, the ideal solution for cleaning the air and recovering valuable resources at the same time. Cetotec condensers can retrieve valuable volatile and aromatic substances from the exhaust air. The recovered liquid is available in concentrated form and can be constantly reintroduced into the fermenter. Condensers are especially recommended for the production of speciality vinegars. For further increasing the yield, condensers can be used in combination with an exhaust air scrubber.

Delivering clean air and recovering valuable resources

Recovery of more than 90% of resources in exhaust air

Minimizing odor emissions in residential areas

Droplet separator reliably prevents the outlet of acetic droplets

Construction completely from stainless steel

Suitable for both inside and outside installation

Description

The robust and compact design of the absorber column and absorber reservoir is complemented by a reliable automation system. The exhaust air, consisting of ethanol and acetic acid is transported through the absorber column and thereby cleaned. By using a dual-stage exhaust air scrubber, the exhaust air is passed through two washing columns in succession, thereby increasing the recovery of volatiles to more than 90%.

Function

The exhaust air scrubber functions on the basis of physical absorption. The resources contained in the exhaust air are washed out of the gas phase and gathered within the washing liquid. The special design of the filling material within the absorber column guarantees a very high surface and therefore leads to an optimal mass transfer during the cleaning. The washing liquid can be used for mash preparation or dosed back into the vinegar fermenter. In case of using the fed-batch process the liquid can be dosed into the fermenter during the charge phase.

Available Sizes

Standard sizes: 300 – 4000 m3 / h air volume. Exhaust air scrubbers and condensers can be constructed based on customer requirements and tailored to local specifications.

Matching answers for the usual questions

Is it possible to re-use the wash water?

Yes, the wash water is collected in a reservoir and especially when using the fed-batch process, the wash water can be dosed into the fermenter during the cycle as charging water.

When do I use an air scrubber and when is a condenser recommended?

Cetotec exhaust air scrubbers offer the ideal solution for cleaning the air and simultaneously recovering valuable resources, especially for industrial vinegar fermenters in the production of spirit vinegar, as the wash water can be returned to the fermenter.

Condensers are particularly recommended for the production of wine vinegars and specialty vinegars.

We provide made to measure equipment.

Special Fermenter SF6

Our recommendation:

Special Fermenter SF6

Your request has been successfully submitted!

We will get in touch with you soon via email.

CETOTEC GmbH

Zilzkreuz 23

53604 Bad Honnef

Germany

Phone: +49 2224 9000 00

Mail: info@cetotec.com