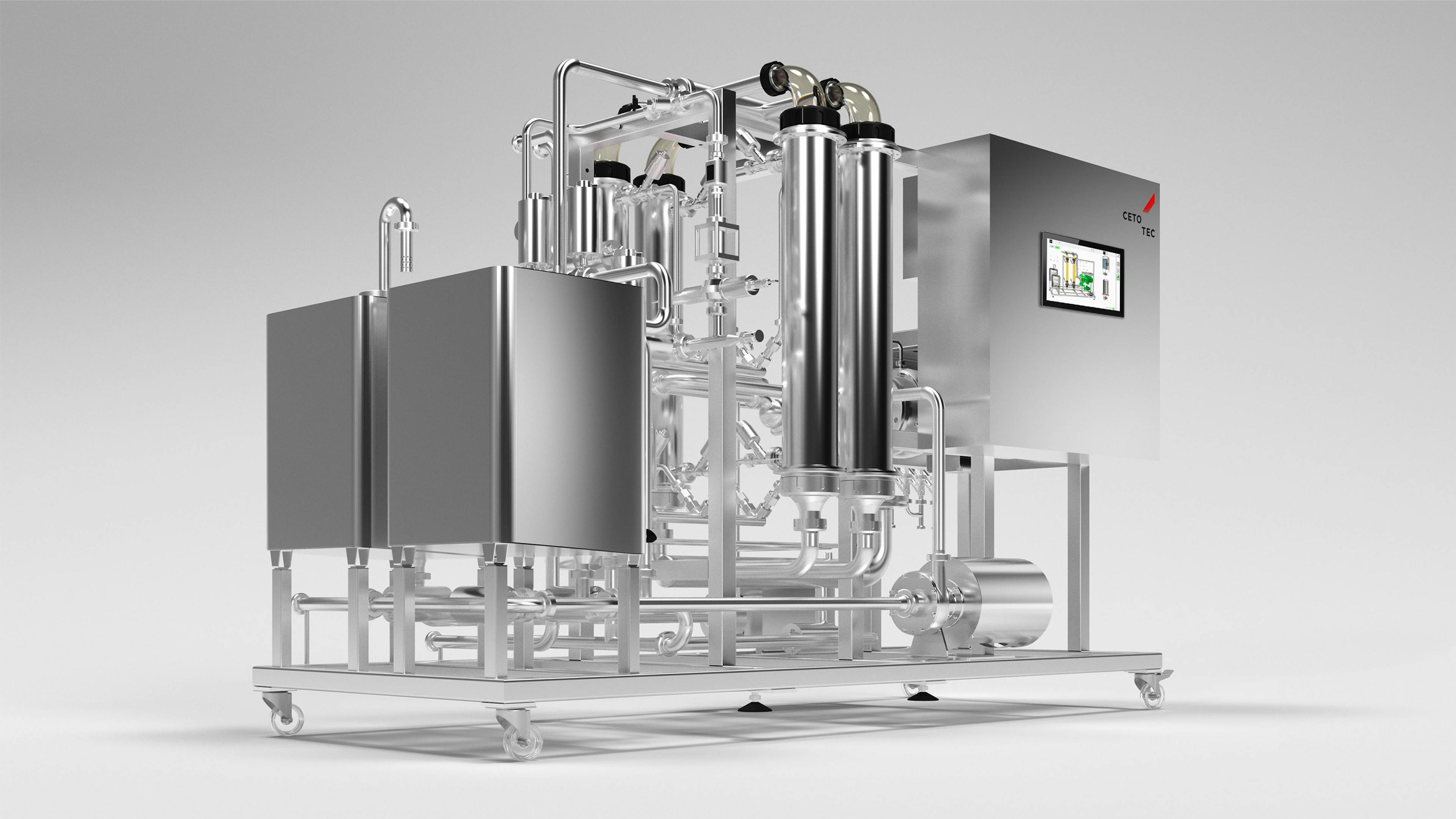

Aerator for vinegar technology

Vinegar production poses high technological requirements with regards to the optimal aeration of acetic acid bacteria during the fermentation process. For this purpose Cetotec delivers aerators with highest possible oxygen enrichment and optimal mixing results of fermentation liquid, air and substrates at the same time.

Technological leading aerator design

Best yield / energy consumption ratio worldwide

Usage of energy efficient motors (IE3)

Optimized charge distributor for the mixing of dosed alcohol

Modular construction method enables smooth maintenance and service applications

Description

Oxygen transfer and distribution are the most important factors in submerse vinegar fermentation. An intensive mixing of air, alcohol, water and nutrients as well as the homogenous distribution of this mixture within the entire working volume of the fermenter are the basic principles for modern and high performing vinegar production. Cetotec aerators offer you all these factors finely tuned to perfection.

Function

The oxygen supply and distribution is based on a carefully designed aerator architecture consisting of a hydrodynamically optimized rotor and stator couple. The goal is to introduce the highest quantity possible of small air bubbles into the fermenter and therewith bring the aeration as well as the homogenous distribution of the mixture to perfection. This highly efficient supply to the vinegar bacteria enables the achievement of an optimal yield to energy consumption ratio.

Available Sizes

Cetotec delivers aerators for all vinegar fermenter sizes up to a motor power of 132kW.

Matching answers for the usual questions

Is it possible to equip an old fermenter with a new aerator?

This has to be checked case by case and depends on the tank geometry as well as the cooling capacity. We are happy to offer you our support.

Which maintenance operations need to be performed regularly?

Approx. every 6-10 years the motor should be overhauled and the mechanical seal replaced.

We provide made to measure equipment.

Special Fermenter SF6

Our recommendation:

Special Fermenter SF6

Your request has been successfully submitted!

We will get in touch with you soon via email.

CETOTEC GmbH

Zilzkreuz 23

53604 Bad Honnef

Germany

Phone: +49 2224 9000 00

Mail: info@cetotec.com